We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

DICOTA's sustainable initiative

DICOTA's biggest initiative to date is to introduce a wide range of notebook bags whose main material is made from recycled PET bottles. In 2008, the owners decided to start looking for environmentally friendly materials. Until then, all carrying solutions were produced from polyester, which is an artificial fabric made by mixing ethylene glycol and terephthalic acid and is therefore a kind of plastic.

Under the motto "Green IT", DICOTA launched the first two bags made of natural materials in 2009. The messenger bags with an alpine look were made from environmentally friendly cotton canvas and leather. The first step has been done and the development team continued to search for materials that reduce the ecological footprint. In 2010, the first collection made from recycled PET bottles was created under the name RECLAIM. Recycled polyester (rPET polyester) requires 59% less energy to produce than conventional polyester. The collection of 16 models was very well received by customers and was sold over 200,000 times.

The experience gained, the improvement of the quality of this material and the definition of sustainability as one of DICOTA's 5 long-term strategic goals led to a far-reaching decision in 2018; existing and future bag collections are to be made from sustainable materials. With this, it was decided that sustainability will not just be a buzzword, but the strategic direction of the company.

In addition to the collections that have already been launched with recycled materials, DICOTA has also decided to convert existing collections to sustainable materials. This is also the case with the best-selling Eco BASE collection, of which more than 650’000 bags have been sold since the switch of the main material.

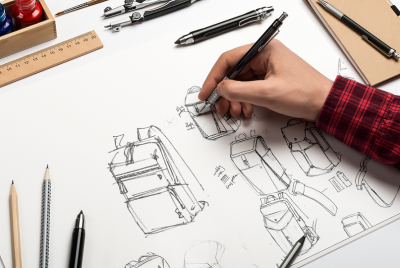

This decision has made it possible to increase the percentage of eco bags in the portfolio. From 20 % in 2019 to 80% in 2021 and an incredible 95% in 2023.

Some impressive milestones were also achieved during this period. In April 2022, the mark of one million Eco Bags produced was cracked. With the CO2 emissions saved by the end of 2022, one could have flown around the world 400 times. To date (May 2023), more than 12 million PET bottles have found their second use in a DICOTA Notebook case.

The work is not done yet, by 2024 the remaining 5% of the carrying solutions will also be converted to sustainable materials.

A sustainable solution for technical accessories is also being explored to complete the range. However, sustainability should not only play a role in the products, which is why some of the packaging has already been improved. The hangtags of the carrying solutions are made of

FSC-certified paper and printed with soy-based ink. Unlike conventional petroleum-based ink, soy-based tine is more environmentally friendly and based on renewable raw materials. To minimise waste for the end user, all packaging has been reduced to a minimum.

In 2021, the project "Smart Logistics Optimisation" was launched to optimise logistics processes. Even before the project started, it was clear that transport should be carried out by new, environmentally friendly ships whenever possible. The alternative transport by ship and rail means that CO2-intensive air freight transport can be avoided. To make the best use of transport and storage space, empty spaces in the boxes were minimised and the boxes strategically stacked. The partners for transportation in Europe are all EcoVadis certified. Returned cartons are reused where possible to reduce waste. Last but not least, the new, optimised location of the warehouse in Germany saves more than 100 truck journeys per year.

Almost the entire DICOTA team is involved in this initiative. From the decision of the company owners to the product manager who looks after the manufacturers, collections and quality standards. The design team worked on the smart designs and discreet labelling of the eco products. The marketing team ensures broad communication and the sales team takes the important message to the customers.

Global Recycling Standards (GRS) certified the materials made from recycled PET bottles.

Recycling PET bottles and processing them into textile fibres has several advantages. It conserves natural resources and minimises waste. Reuse prevents plastics from ending up in landfills or the water cycle, where they take around 450 years to biodegrade. Studies show that recycling polyester uses up to 53 per cent less energy and reduces CO2 emissions by around 54 per cent compared to the production of virgin polyester. One million PET bottles are sold worldwide every minute, or 1.44 billion a day. And only 7% of the bottles sold end up in a recycling facility.

We keep track of the current data and publish the latest DICOTA recycling figures every six months. As of 1 April 2023 they are as follows: 12.3 million bottles were recycled in over 1.4 million bags. You could fly around the world more than 400 times with the resulting CO2 savings.

When the initiative was launched in 2009, demand for sustainable products was limited in some regions and countries because environmental awareness was not as high as it is today. As a result, products made from recycled materials were sometimes considered inferior.

This has changed. As society's awareness of environmental issues grows, so does the demand for sustainable products. Customers value stability, durability and maximum functionality during a long product lifecycle. As a pioneer in the IT industry with a comprehensive portfolio of cases made from recycled materials, DICOTA has been able to convince not only existing customers, but also many new ones.

We care about the environment and the people!

As sustainability is one of DICOTA's five strategic goals, there are other issues that will be addressed as part of this medium-term strategic initiative.

In general, work on Corporate Social Responsibility (CSR) is ongoing. As a member of amfori BSCI, DICOTA is strongly committed to improving working conditions in global supply chains. The amfori BSCI eleven-point charter includes comprehensive worker protection as well as provisions on health and safety and equality in the workplace. The code of conduct also includes protection against child labour and training for young people. Close cooperation with suppliers ensures that the comprehensive certification criteria are continuously implemented. All partners undertake to fully comply with the Code of Conduct and to promote fair and social working conditions on site.

DICOTA contributes to nature conservation by planting a tree for every pre-registration in the DICOTA CLUB (a partner programme for SMB resellers). In addition, once a year sustainable activities take place in the various regions. For example, trees are planted, meadows and fields are restored to their natural state or litter is collected.

We also support the non-profit organisation Labdoo. Used laptops are collected and an additional €25 is donated for each one. The bhz Stuttgart e. V. also received a donation from DICOTA. This enabled the association, which promotes the participation of people with disabilities in work, life and leisure, to purchase new professional sewing machines.

Further activities in these areas are being planned and implemented on an ongoing basis.